News

Andritz starts up sludge drying plant at Eldorado Brasil Celulose

International technology group Andritz, which supplied the technology and developed the new biological sludge drying plant for Eldorado Brasil Celulose’s pulp mill in Três Lagoas, Brazil, celebrated the plant’s successful start of operations. This project represents another step forward in Eldorado’s strategies to transform waste into energy and enhance the environmental efficiency of its operations.

Kemijarvi Biorefinery appoints Dr. Markku Hämäläinen to its Board of Directors

Kemijarvi Biorefinery Ltd. is pleased to announce the appointment of Dr. Markku Hämäläinen as a new member of its Board of Directors, effective 1 January 2026. Dr. Hämäläinen brings decades of international leadership experience in the forest industry, paper and board manufacturing, and large-scale industrial transformation.

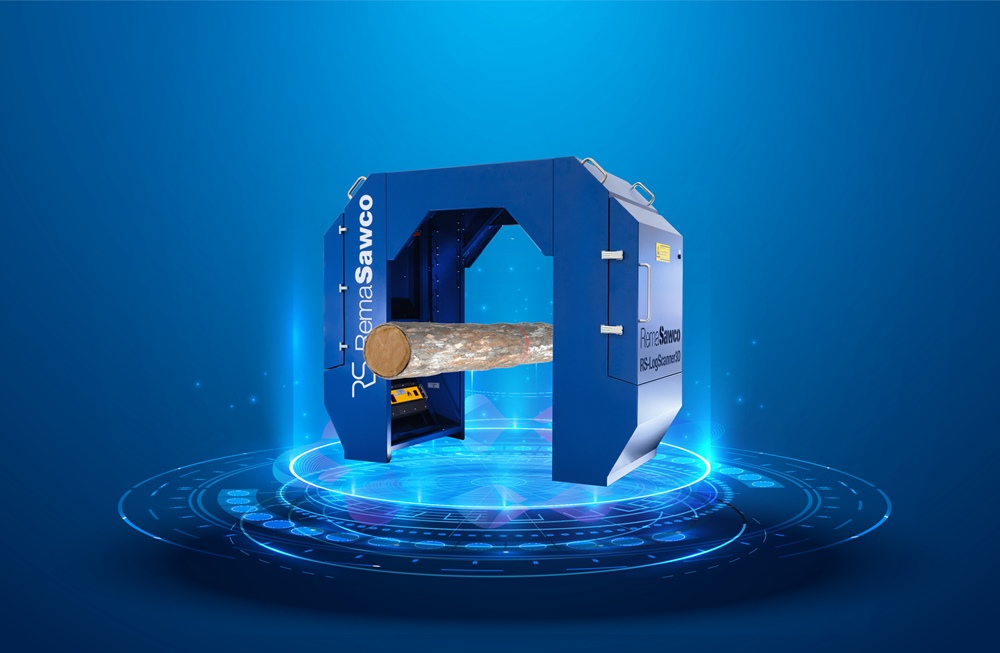

RemaSawco receives order worth just over SEK 2.4 million from Högland Anundsjö sawmill

Högland's Anundsjö sawmill and RemaSawco have signed an agreement for a comprehensive upgrade of the sawmill’s log sorting station. The total order value amounts to just over SEK 2.4 million.

Yanpai expands nonwovens capacity with two new Andritz needlepunch lines

Zhejiang Yanpai Filter Technology Co., Ltd. (hereinafter referred to as “Yanpai”) has placed an order with international technology group Andritz for two high-performance needlepunch lines. The equipment will be installed at Yanpai’s headquarters facility in Tiantai County, China. Commissioning is scheduled for the third quarter of 2026. These two lines are specially designed for the efficient processing of high-end nonwovens. They will increase Yanpai’s nonwovens production capacity and support the company’s entry into new applications.

SCA on CDP’s sustainability A-List 2025

SCA has earned a place on the Carbon Disclosure Project’s (CDP) prestigious A-List for 2025 – the highest possible rating – in the categories of Climate and Forests. The award signifies that SCA ranks among the global top performers in terms of transparency, strategic sustainability work, and concrete actions in these areas. In this year’s CDP evaluation, SCA is placed on the A-List in the Climate and Forests categories.

Cooperative organisations strengthen the Swedish economy

A new report from Svensk Kooperation shows that cooperative enterprises in Sweden have increased their turnover by 27 percent over the past decade and now account for around ten percent of GDP. Södra is one of the largest players, contributing to a resilient and sustainable forestry sector – where members have influence and share in the value created.

Södra wins Växjö municipality’s timber construction award 2025

Södra has been named the winner of Växjö Municipality’s Timber Construction Award 2025 for its long-term and sustainable approach to timber construction. The award recognises those driving progress in sustainable building and inspiring continued innovation.

Södra tests carbon capture technology in Värö

In early 2026, a pilot project for carbon capture will be launched at the Värö industrial site. The initiative aims to build knowledge around the technology and explore new business opportunities using biogenic carbon dioxide as a raw material. The pilot is part of Södra’s long-term strategy to increase the value of every tree, strengthen competitiveness and contribute to more profitable forest estates. By testing new technology to capture biogenic carbon dioxide in an industrial setting, Södra seeks to explore how this resource can be refined and used in new applications without increasing forest harvesting.

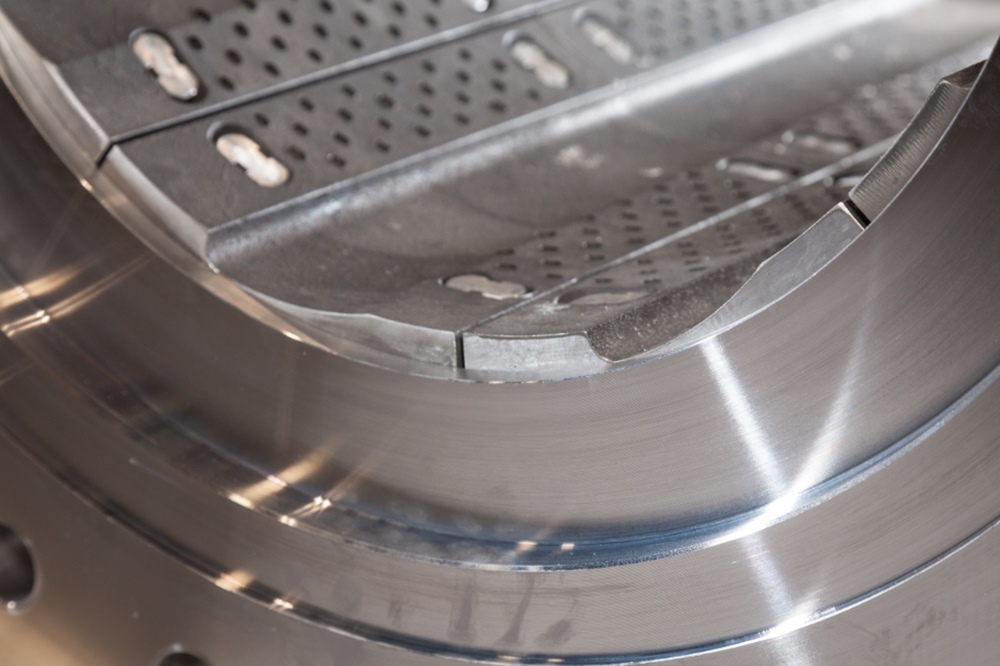

Metro Decorative places repeat order for advanced Andritz pressurized refining system

Metro Decorative Pvt. Ltd., India has placed an order with international technology group Andritz for the supply of a second pressurized refining system to its medium-density fiberboard (MDF) production facility in Kashipur, Uttarakhand. The order value will not be disclosed. It is included in Andritz’s order intake for the third quarter of 2025.

Bellmer successfully closes the acquisition of Cellwood Machinery AB

Bellmer GmbH, international supplier of paper and board machinery, is pleased to announce the successful closing of its acquisition of Cellwood Machinery AB, a glob-ally recognized Swedish manufacturer of systems for wastepaper recycling and bioener-gy pre-treatment. Following the signing of the agreement in mid-September 2025 and the completion of all regulatory and contractual conditions, the transaction was officially closed at the end of October 2025.

Andritz strengthens boiler service business by acquiring Allen-Sherman-Hoff

International technology group Andritz has acquired Allen-Sherman-Hoff from US-based Babcock & Wilcox Enterprises, Inc., further strengthening its offering of boiler solutions and related services. The acquisition supports Andritz’s long-term strategy to grow its aftermarket and service business by offering customers complete lifecycle solutions and support.

Södra adapts its organisation to strengthen competitiveness

To navigate a challenging global landscape and be better prepared for the future, Södra has initiated an action programme. The aim is to strengthen Södra’s long-term competitiveness through improved profitability and new ways of working. The planned actions will affect the entire organisation and result in 200 redundancies.